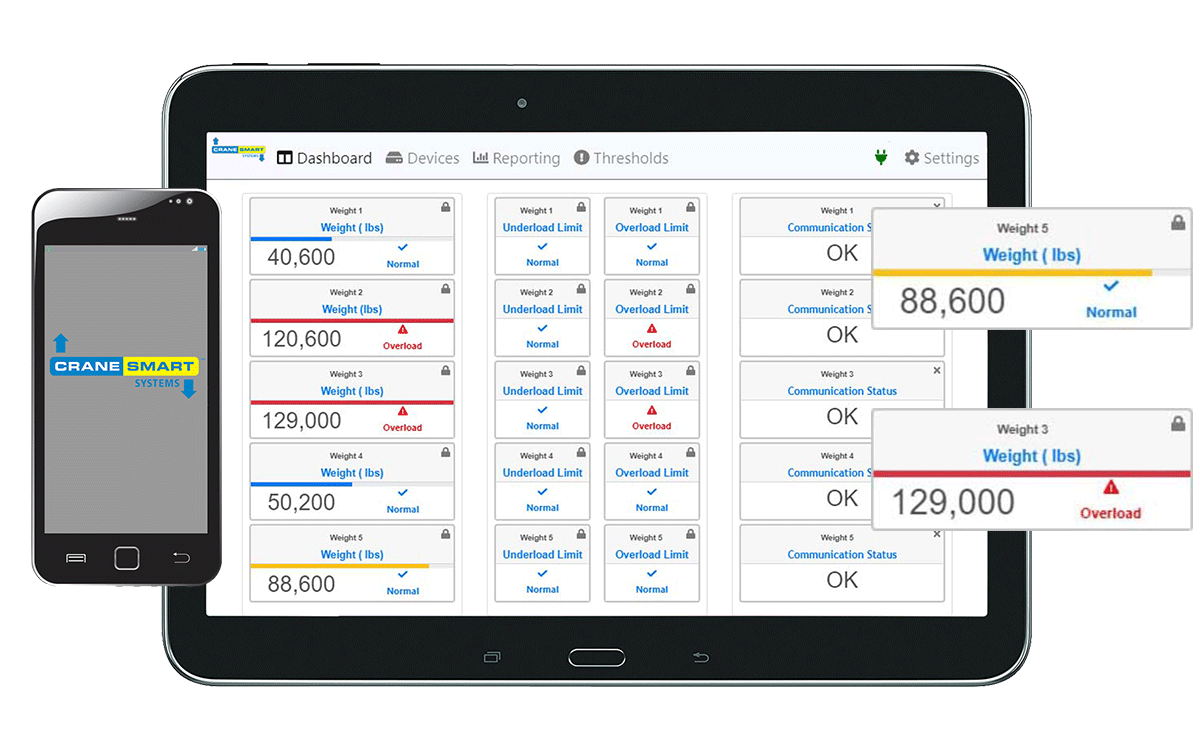

Jobsite Foreman App

The Winchsmart System has a jobsite foreman application that allows supervisors to view operation data effectively and monitor the load status of multiple machines at once, while recording values for analysis.

• The application can be customized by the user.

• Provides complete status at a glance, tailored to any set of specific needs.

• All alarms are clearly displayed and logged, indicated by type, time, date and status.

• Loads can be viewed after the fact to help you predict your equipment needs in similar situations.

• The Winchsmart System has an HTML interface that allows for viewing from any phone, tablet or laptop and can be access via a local WiFi connection. Internet connection is not required.

• The system can be accessed via cell phone network if a connection is available. Look at loads live from the office.